Paint Manufacturing

What is paint and how is it made?

To most people, paint is the colour on the walls of their home, the colour of their car, boat or caravan.

Paint is more than just the colour though; it is a material that is applied as a liquid and dries by a variety of chemical processes to a solid.

We apply paint for:

- Decoration

- Protection

- Identification

- Sanitation

What is paint made of?

Paint typically consists of pigment, resin, solvent and additives:

Pigment – to provide colour, hiding and control gloss.

Pigments are usually divided into two groups. One called ‘Prime Pigments’ includes pigments such as Titanium Dioxide (white), Chrome Green Oxide, Yellow and Red Iron Oxides, etc. The other group of pigments is called ‘Extender Pigments’ and includes Calcite (Calcium Carbonate), Talc (Magnesium Silicate), Mica, Barytes (Barium Sulphate), etc.

Resin – the binder to hold the pigment particles together and provide adhesion to the surface painted.

Waterborne paints most often use acrylic emulsion polymers as binders. These come in a wide variety of types and combinations. Common acrylic polymer types are based on monomers such as methyl methacrylate and butyl methacrylate. Traditionally, lower cost paints have been formulated on PVA (Poly Vinyl Acetate) binders.

Solventbased resins come in a very wide range of types. The most common solvent based resins are termed ‘alkyd resins’ that are normally used in enamel paints. Urethane alkyds often used in clear varnishes. Protective coating resins include types such as Epoxy, Urethane, Polysiloxane and Moisture Cured Urethane.

Solvent – to act as a carrier for the pigments and resin – the solvent may be organic (such as Mineral Turps) or water.

Solvents are various low viscosity, volatile liquids. They include petroleum mineral spirits and aromatic solvents such as benzol, alcohols, esters, ketones, and acetone. The natural resins most commonly used are lin-seed, coconut, and soybean oil, while alkyds, acrylics, epoxies, and polyurethanes number among the most popular synthetic resins. Additives serve many purposes. Some, like calcium carbonate and aluminum silicate, are simply fillers that give the paint body and substance without changing its properties. Other additives produce certain desired characteristics

Additives – to enhance certain properties such as ease of brushing, mould resistance, scuff resistance, drying and sag resistance.

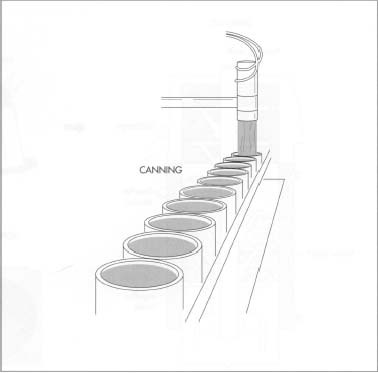

Paint canning is a completely automated process. For the standard 8 pint paint can available to consumers, empty cans are first rolled horizontally onto labels, then set upright so that the point can be pumped into them. One machine places lids onto the filled cans while a second machine presses on the lids to seal the cons. From wire that is fed into it from coils, a bailometer cuts and shapes the handles before hooking them into holes precut in the cans.in paint, such as the thixotropic agents that give paint its smooth texture, driers, anti-settling agents, anti-skinning agents, defoamers, and a host of others that enable paint to cover well and last long.